FTC disclosure tour-de-force here. The following article was last updated on Nov 20, 2025 ...

Demystifying The Tool Calibration Process

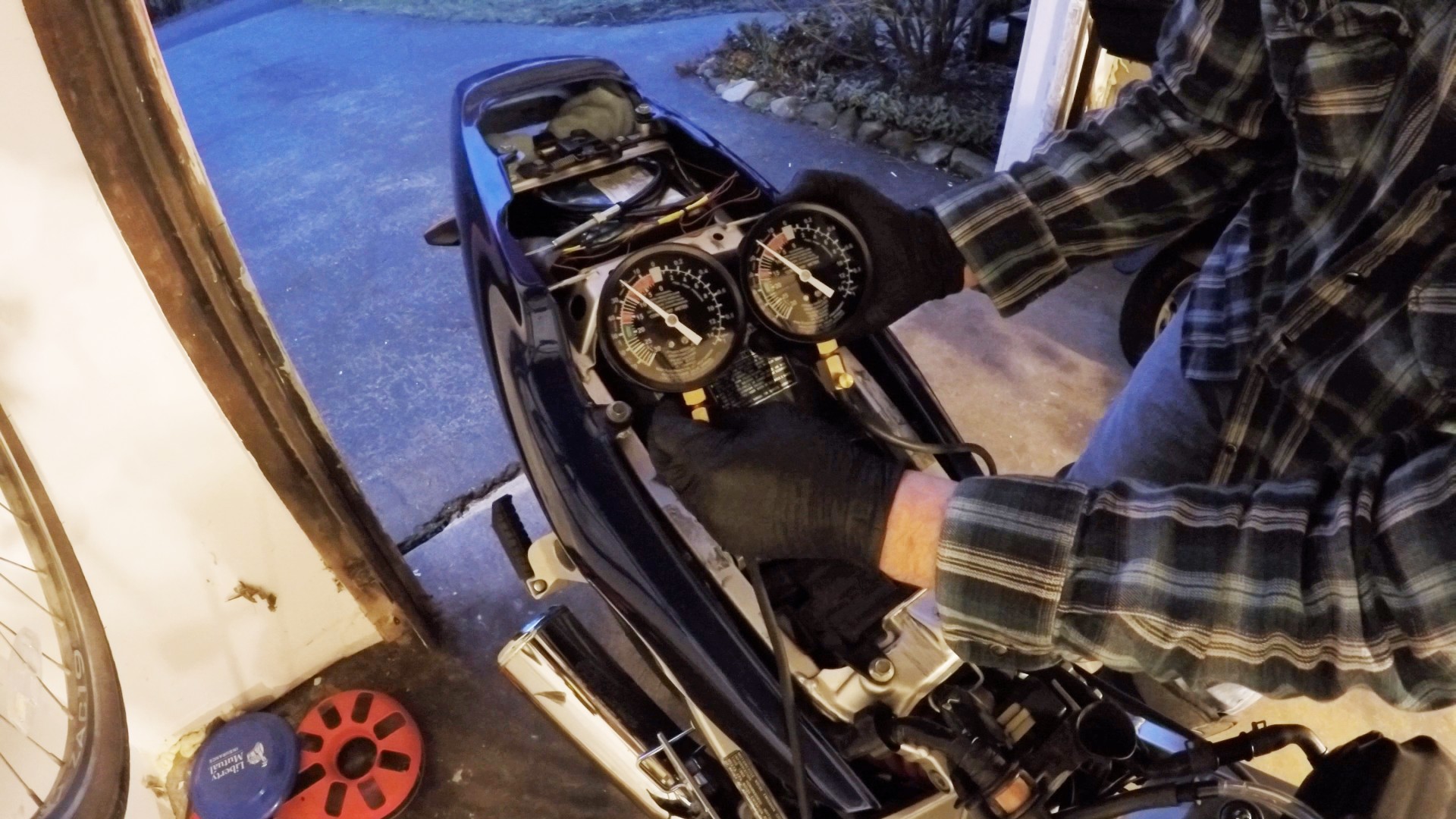

In the past, whenever I'd see the word "calibrate," I'd set a given task aside and move on to something else. A recent effort to synchronize V-twin carburetors on a 1988 Honda Hawk GT inspired me to move beyond this tendency. With our recent purchase of four carburetor synchronization vacuum meters, I felt it an appropriate opportunity to experiment.

“A bit of carburetor tool calibration experimentation allows for all of them to be stressed simultaneously, greatly simplifying the process.”

Before I elaborate on the matter, note that you can synchronize twin carburetors without much difficulty using only one meter. First, plug one carb's outlet adapter with your finger and then connect said meter to the other before taking a mental record of its reading. Next, switch which outlet you plug versus meter and synchronize accordingly, repeating the process until you hit common ground, per the instructions in your service manual. If you're new to this, a quick primer on carburetor tool calibration can save time and guesswork.

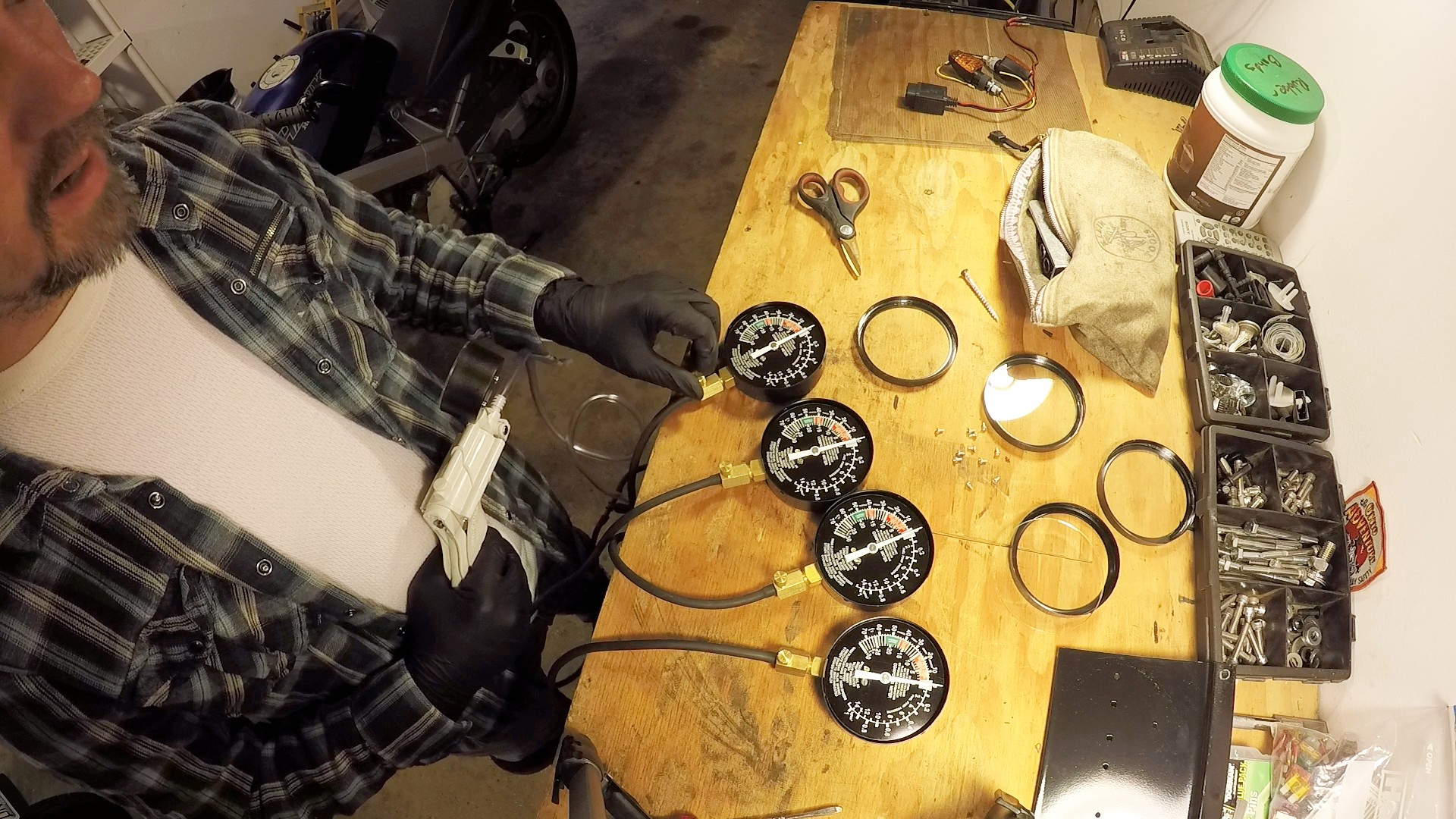

The only information I collected for multi-unit calibration is that you should stress each individual meter under an identical load before you make adjustments. A bit of ingenuity allows you to stress all of them simultaneously, greatly simplifying the process. Below is what I came up with.

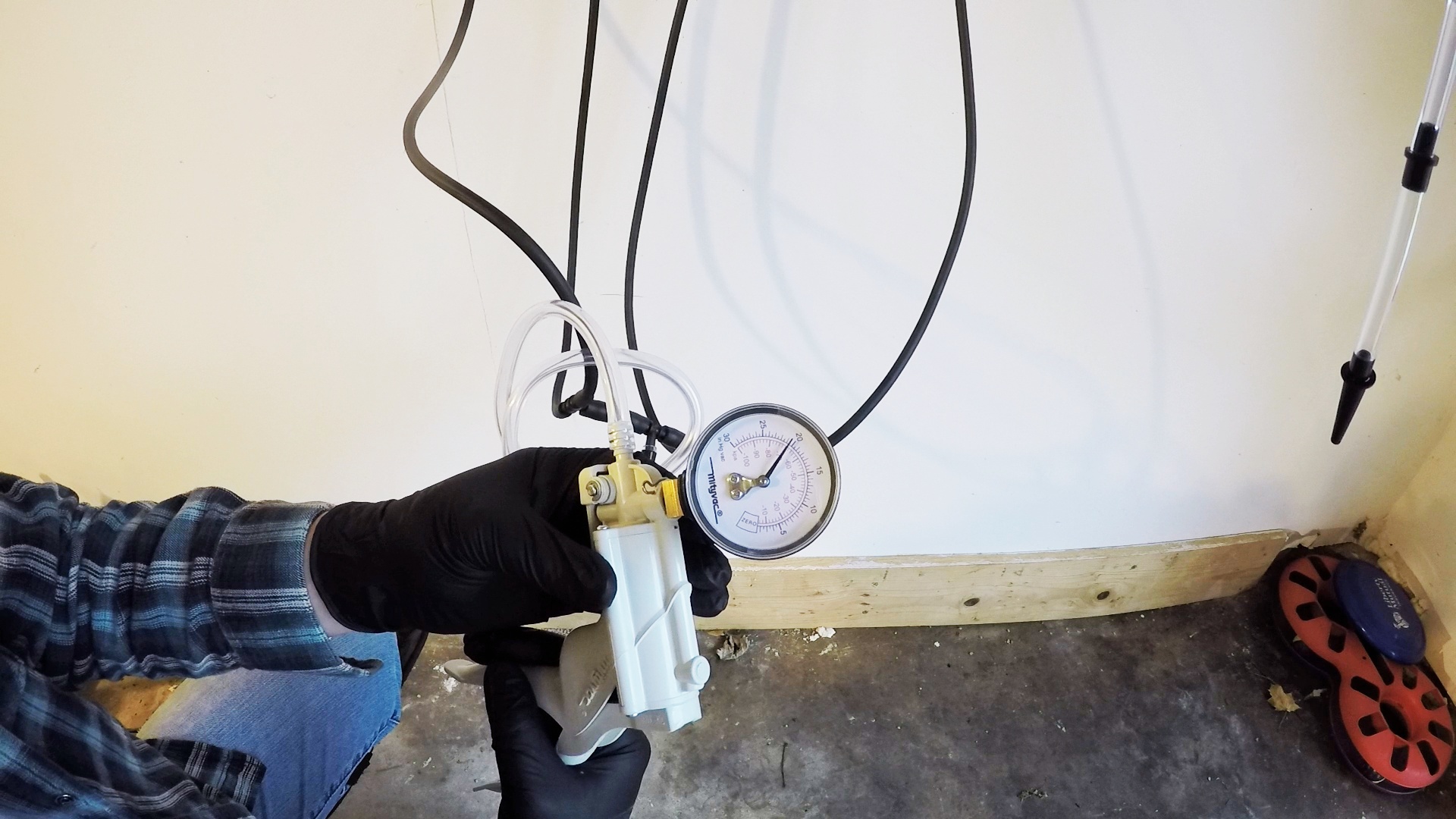

Three T-connectors and a bit of vacuum hosing keep the Mityvac hand pump pressure(s) completely balanced. Four outlets, equidistant from one another, receive the same draw via a vacuum connection at the direct center. Now it's just a matter of assembly.

For this specific set of vacuum meters, rotate each knob clockwise or counterclockwise to adjust the sensitivity. Loosening everything before slowly tightening is somehow a more accurate way to land in the "butter zone" for our Mightyvac. As the photo below points out, each dial is slightly off its mark, so calibration is definitely necessary.

The service manual for our Hawk GT states that the carburetors should be within 40 mm of one another with regard to vacuum pressure. I prefer more exacting figures, my end goal being a nearly identical reading. This means I'll need my meters to be equally accurate, if not more.

My vacuum meters have a front-side adjustment screw that you can see behind the lens. A twist of the wrist exposes them all so that I can set things to an (inaccurate) zero before applying a vacuum and adjusting with more scrutiny. Pumping the Mityvac and tweaking the meters at different levels takes a bit of patience/precision but the end result is well worth it for carburetor tool calibration.

Balancing friendly outside advice against my own limited understanding of vacuum geometry, this slightly compulsive approach to calibrating four carburetor synchronization meters simultaneously has turned out to be both efficient and effective. While my gut tells me that mercury-based tools are easier to work with, I like that these meters are useful in other ways (one tool, multipurpose). For complete details on how I went about all of the above, see the following video ...

How Do You Calibrate Your Accuracy Tools?

Vacuum meters are just the beginning. Many other tools involve a more elaborate process for calibration. What tools have you calibrated in the past? Was the process difficult and if so, how? Your input is invited. Leave a comment and/or write an article!

Thoughts gone wild? Write an article!